Pneumatic Diaphragm pump

Stainless steel sanitary diaphragm pump particularly designed to meet the requirements of the food, beverage, pharmaceutical and cosmetic industries. Lubrication free air distribution system, maintenance free ball check valve system and total visual inspection of the wetted parts are some of the major features for this pump series

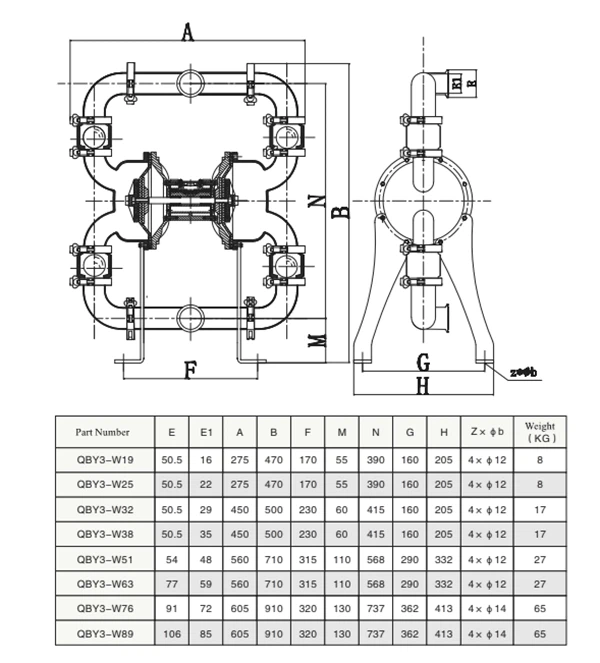

QBY3-W sanitary grade pneumatic diaphragm pump

Products Description

QBY3-W sanitary grade pneumatic diaphragm pump is a specialized type of pump designed for applications in industries such as food and beverage, pharmaceuticals, and biotechnology, where hygiene and cleanliness are crucial. Here are some key features and uses:

- Material: made of stainless steel, which is highly resistant to corrosion and easy to clean, making it suitable for sanitary applications.

- Diharge pressures, making them suitable for handling sensitive or viscous fluids without contamination.

- Saniaphragm Design: These pumps use a diaphragm as the primary moving component. This diaphragm flexes to create suction and disctary Connections: They typically have sanitary fittings and connections, such as tri-clamp or sanitary flanges, to ensure a hygienic process and easy disassembly for cleaning and maintenance.

- Pneumatic Operation: These pumps are often operated by compressed air, which allows for precise control and is useful in environments where electric motors could pose a hazard.

- Applications: Common applications include transferring liquids like dairy products, beverages, pharmaceutical ingredients, and cosmetics, where maintaining product purity is essential.

- Hygienic Standards: They are designed to meet or exceed industry hygiene and sanitation standards, such as those set by the Food and Drug Administration (FDA) and 3-A Sanitary Standards.

- Self-Priming: Many diaphragm pumps are self-priming, meaning they can evacuate air from the suction line and start pumping without external assistance.

Products Specification

|

Product Name |

Sanitary diaphragm pump |

|

|

Model |

QBY3-W |

|

|

Material |

Stainless steel 316 /304 |

|

|

Max working flow |

568L /min |

|

|

Max suction height |

5.48m |

|

|

Outlet pressure |

8.4kg |

|

|

Inlet/outlet size |

DN3 |

|

|

Air inlet size |

1/2 in |

|

|

Particle diameter |

6.4mm |

These pumps play a critical role in industries where product integrity, cleanliness, and precise fluid handling are paramount.

Stainless steel sanitary diaphragm pump particularly designed to meet the requirements of the food, beverage, pharmaceutical and cosmetic industries. Lubrication free air distribution system, maintenance free ball check valve system and total visual inspection of the wetted parts are some of the major features for this pump series

QBY3-W sanitary grade pneumatic diaphragm pump TYPICAL APPLICATIONS

●Dairy products:Milk, cream, yogurt, cream cheese, melted cheese

●Grossery:Ketchup, mayonnaise, tomato products, mustard

●Beverages:Flavours, colouring, fruit juice

●Bakery:Dough, ingredients

●Brewery:Beer, flavours, colouring, wort

●Hygiene:Soap, toothpaste, schampoo

●Cosmetics:Cream, alcohol, perfume

QBY3-W sanitary grade pneumatic diaphragm pump Working principle

In the two symmetrical working chambers of the sanitary diaphragm pump, an elastic diaphragm is installed in each, and the connecting rod integrates the two diaphragms.

After the compressed air enters the air distribution valve chamber from the intake joint of the pump, it pushes the diaphragm of the working chamber B, and drives the diaphragm connected by the connecting rod to move synchronously.

At the same time, the gas in the working chamber of A is discharged out of the pump from the back of its diaphragm. When the piston reaches the stroke point, the valve mechanism automatically .The compressed air is introduced into another working chamber to push the diaphragm pump to move in the opposite direction, thus forming a synchronous reciprocating motion of the two diaphragms.Two one-way ball valves are set in each working chamber. The reciprocating motion of the diaphragm causes the volume of the working chamber to change and drives the two one-way balls.The valve opens and closes alternately, so that the liquid is continuously sucked in and discharged.

QBY3-W sanitary grade pneumatic diaphragm pump maintenance

- Regular Inspection: Conduct visual inspections of the pump and its components to check for signs of wear, leaks, or damage.

- Cleanliness: Keep the pump and its surroundings clean. Ensure there's no buildup of debris, dust, or contaminants that could affect its performance.

- Diaphragm Inspection: Regularly inspect the diaphragms for wear, tears, or damage. Replace them if necessary. Diaphragms are critical for the pump's operation.

- Check Valves: Examine the check valves for any blockages or wear. Clean or replace them as needed.

- Supply: Ensure a clean and dry air supply. Moisture or contaminants in the air can damage the pump. Consider using air filters and dryers.

- Tighten Connections: Periodically check and tighten all pump connections, including bolts, clamps, and fittings.

- Lubrication: Lubricate moving parts and seals as recommended by the manufacturer. Ensure you use food-grade or sanitary lubricants if applicable.

- Seals and Gaskets: Check seals and gaskets for wear or leaks. Replace any damaged seals promptly.

- Pressure Relief Valve: Verify that the pressure relief valve is functioning correctly to prevent over-pressurization.

- Documentation: Keep a maintenance log to record inspection and maintenance dates, as well as any issues or repairs.

- Training: Ensure that personnel operating and maintaining the pump are properly trained to do so safely and effectively.

- Spare Parts: Maintain a stock of spare parts specific to your pump model to minimize downtime in case of a breakdown.

- Mnufactuarer Guidelines: Always follow the manufacturer's recommended maintenance schedule and guidelines, as they can vary between pump models.

Hot Tags: Pneumatic Diaphragm pump, China, suppliers, manufacturers, factory, customized, wholesale, low price, in stock, threaded end pipe fittings, exporter of high pressure stainless steel plugs, steam pipe fittings, industrial pipe fittings, pressure resistant valve, retail valve

Send Inquiry